High-Performance Equipment for Every Task

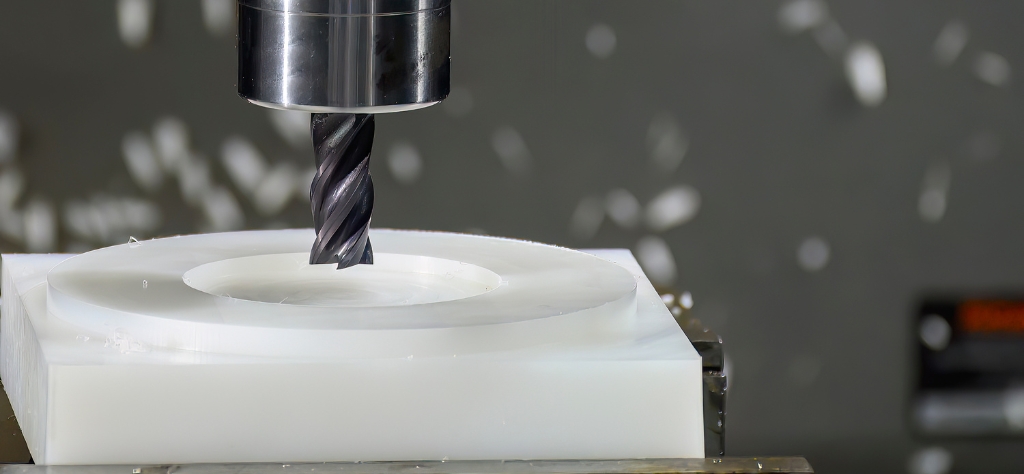

At Mettaluxe, we use high-performance equipment to ensure precision and efficiency in every project. Our workshop features CNC machines, hydraulic press brakes, welding stations, and automated cutting systems, allowing us to handle complex metal fabrication with ease.

We continuously upgrade our machinery to maintain top-quality standards. From precision milling to heavy-duty processing, our advanced tools help us deliver reliable, high-quality results for clients across London and the UK.

High-Performance Machinery

Mechanical Press

◆ Capacity: 100 Tons

◆ Bed Size (WxL): 2' x 3'

Mechanical Press

◆ Capacity: 80 Tons

◆ Bed Size (WxL): 2' x 2.5'

Mechanical Press

◆ Capacity: 50 Tons

◆ Bed Size (WxL): 2’ x 2’

Mechanical Press

◆ Capacity: 20 Tons

◆ Bed Size (WxL): 1.5’ x 1.5’

Mechanical Press

◆ Capacity: 15 Tons

◆ Bed Size (WxL): 1.5’ x 1.5’

Hydraulic Press

◆ Capacity: 5 tons

◆ Bed Size (WxL): 1’ x 1’

Shearing Machine

◆ Cutting Thickness (Max.): 5 mm

◆ Cutting Width (Max.): 72 inches

Spot Welding

◆ Welding Current: 100 kVA

Spot Welding

◆ Welding Current: 45 kVA

CNC Milling

◆ Control: TNC 370

◆ Coordinate-X: 650 mm

◆ Coordinate-Y: 285 mm

◆ Coordinate-Z: 115 mm

CNC Milling

◆ Work-Shop: Configuration

◆ Coordinate-X: 600 mm

◆ Coordinate-Y: 400 mm

◆ Coordinate-Z: 400 mm

Milling

◆ Coordinate-X: 400 mm

◆ Coordinate-Y: 1200 mm

◆ Coordinate-Z: 300 mm

Wire Cut

◆ Control: HF-System

◆ Coordinate-X: 450 mm

◆ Coordinate-Y: 370 mm

◆ Coordinate-Z: 500 mm

Lathe Machine

Lathe Machine

◆ Length: 6 feet

Lathe Machine

◆ Type: Bench

◆ Power: 2 hp

Drill Machine

◆ Type: Micro

◆ Speed: 1400 rpm

◆ Coordinate-Z: 200 mm

Talk to the Experts

Let’s talk!

What Makes Us Stand Out?

With Mettaluxe, you benefit from years of expertise in steel fabrication, ensuring that every project meets the highest standards of precision and quality. Whether it’s for construction, manufacturing, or custom needs, we’re equipped to handle all steel requirements.

Our commitment to innovation and customer satisfaction makes us the trusted partner for your next steel fabrication project. We deliver reliable solutions, using state-of-the-art technology and skilled craftsmanship to bring your ideas to life on time and within budget.

- High-Quality Materials

- Expert Craftsmanship

- Custom Solutions

- Competitive Pricing